Behind the Scenes: A Look at our Investigative Work

Industrial by-products replacing ordinary Portland cement in concrete

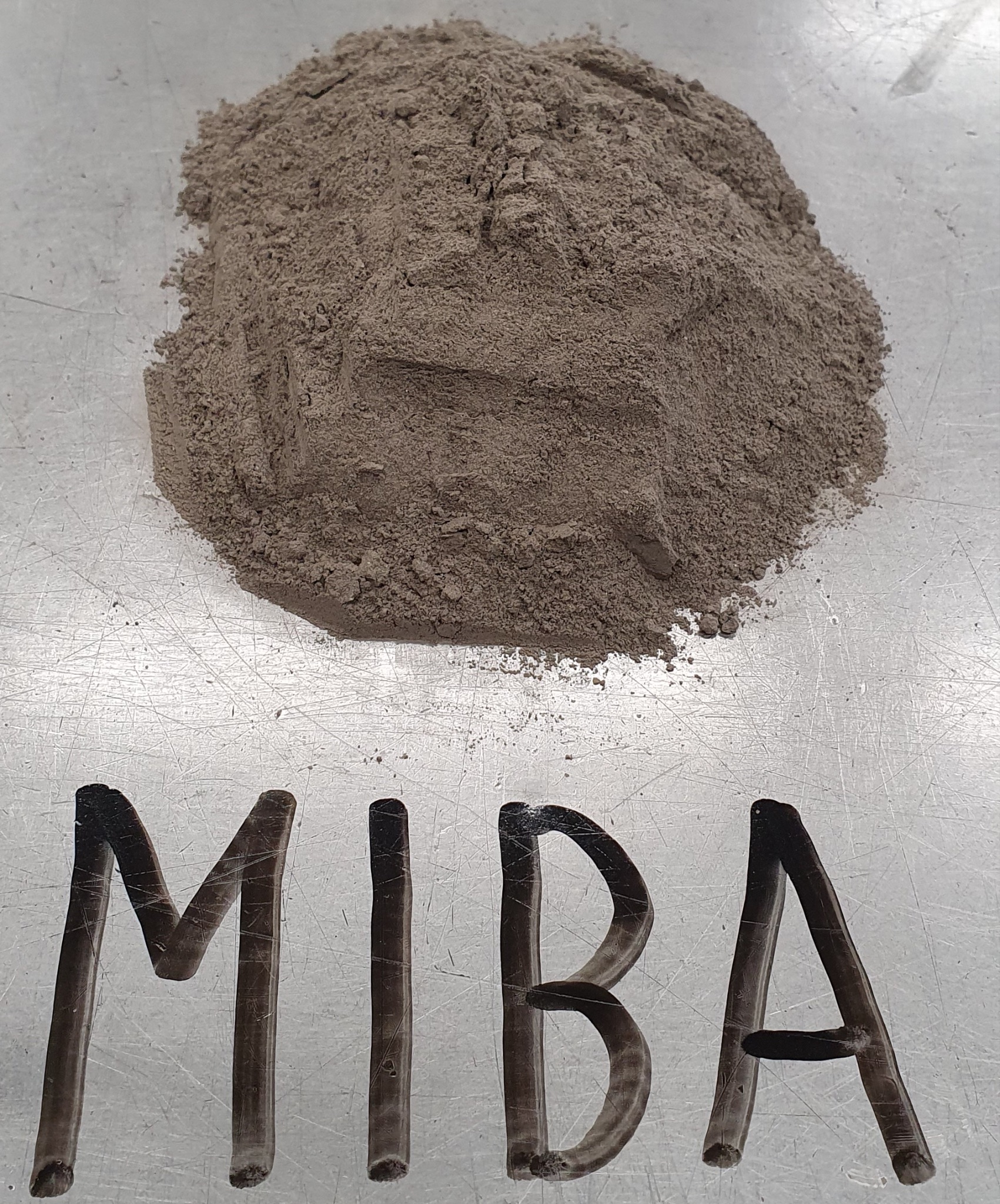

Municipal solid waste incinerator bottom ash, a by-product of the household waste incineration process.

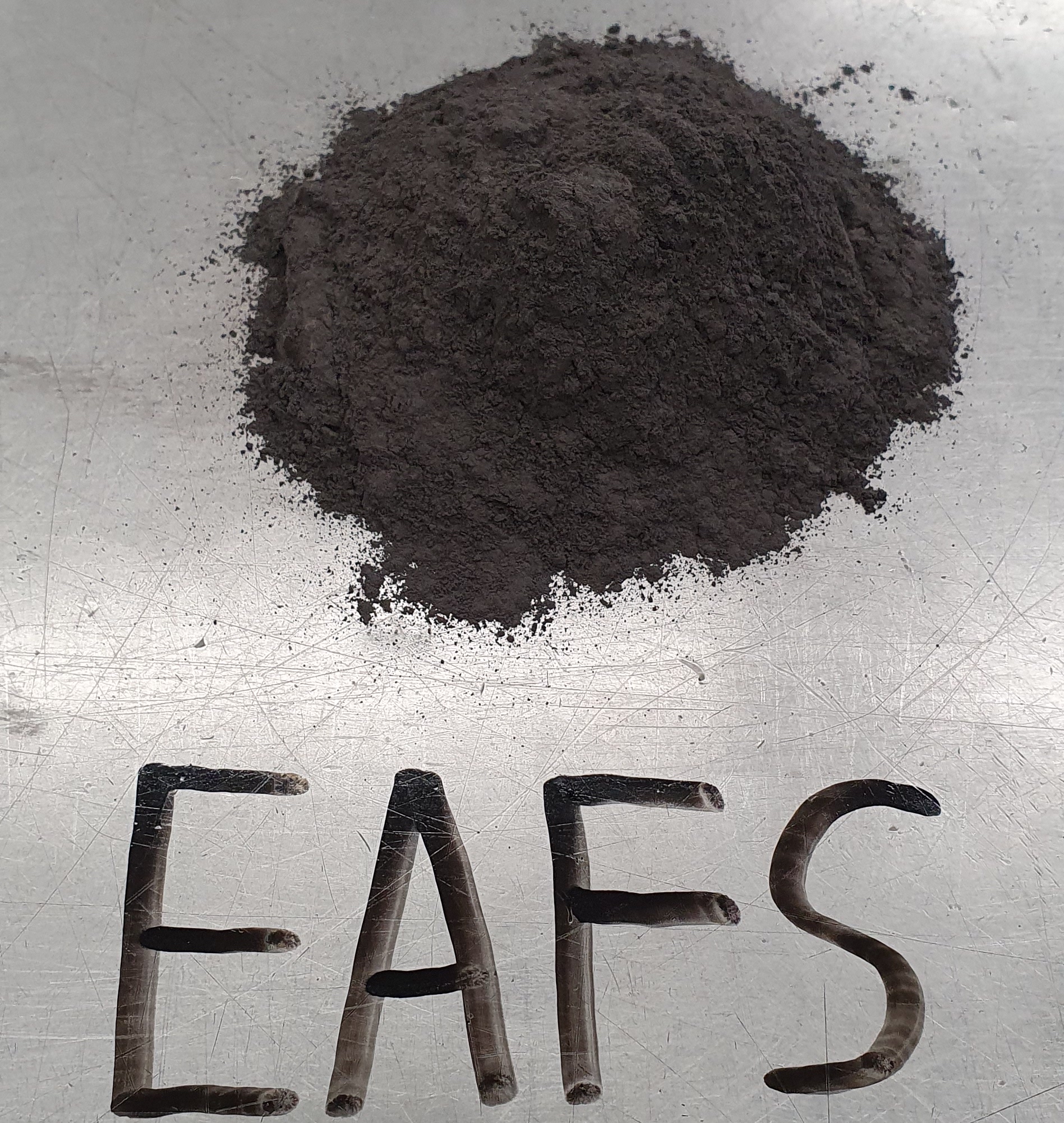

Electric arc furnace slag, a by-product from the steel recycling industry.

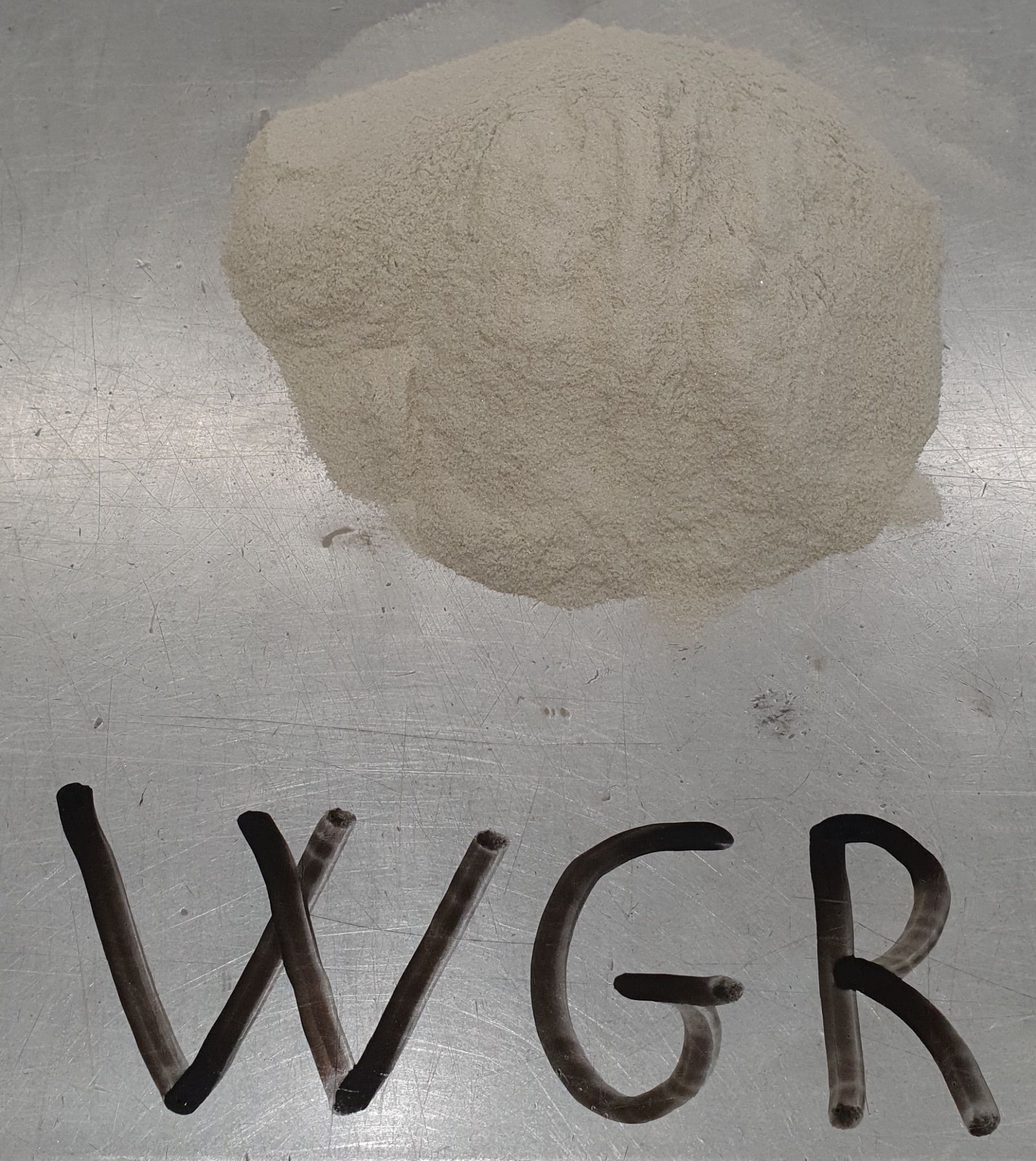

Waste glass rejects sourced from glass recycling facilities.

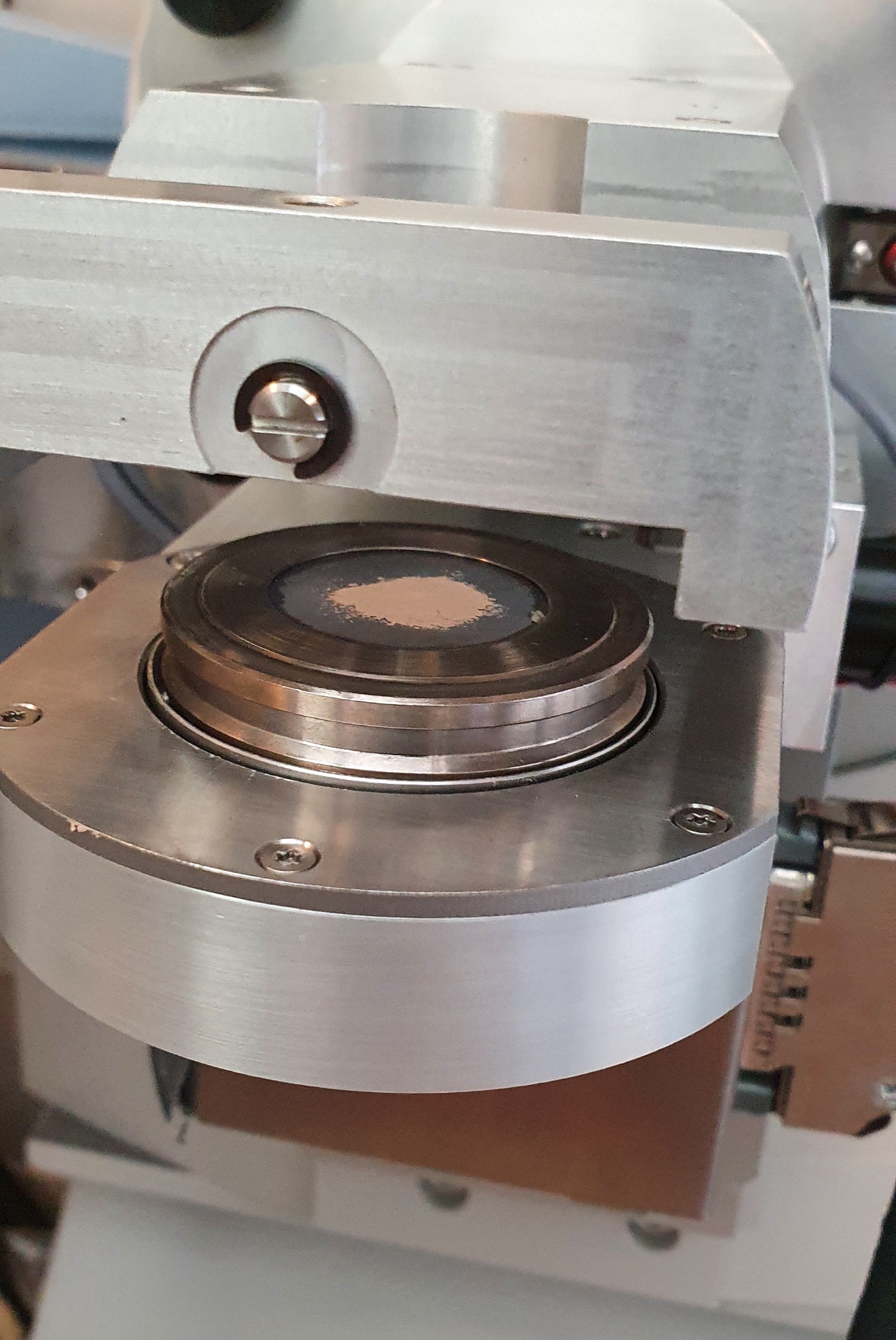

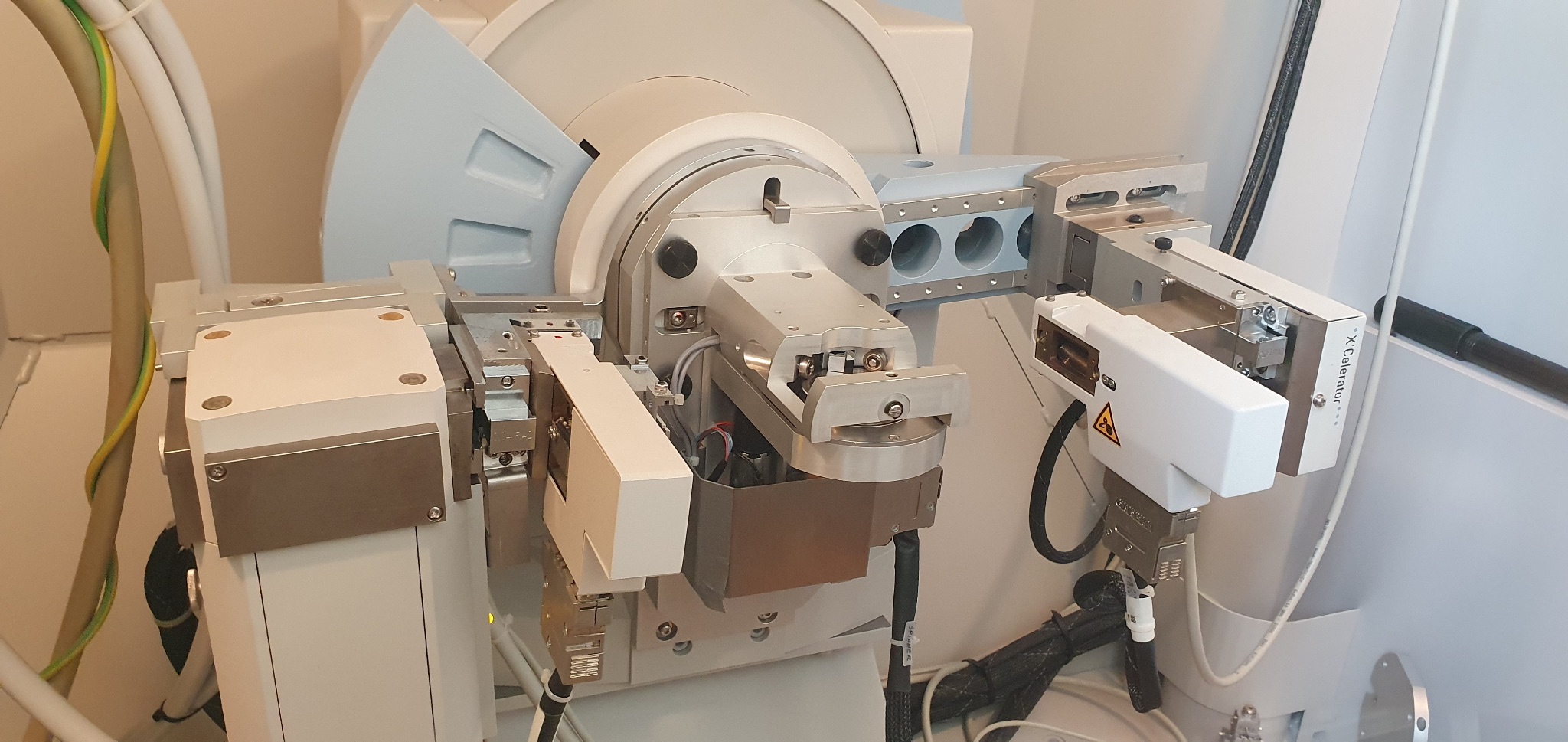

Materials characterisation

The chemical compositions of the materials (raw and sampled from carbonated specimens at different depths) were analysed by means of the following techniques:

Scanning Electron Microscopy (SEM);

X-ray Fluorescence (XRF);

X-ray Diffraction (XRD);

Particle Size Distribution (PSD);

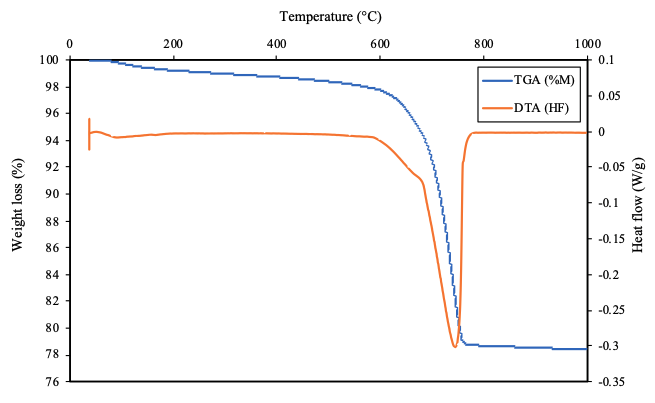

Thermogravimetric Analysis (TGA);

Fourier-Transform Infrared Analyses (FTIR);

Nuclear Magnetic Resonance (NMR).

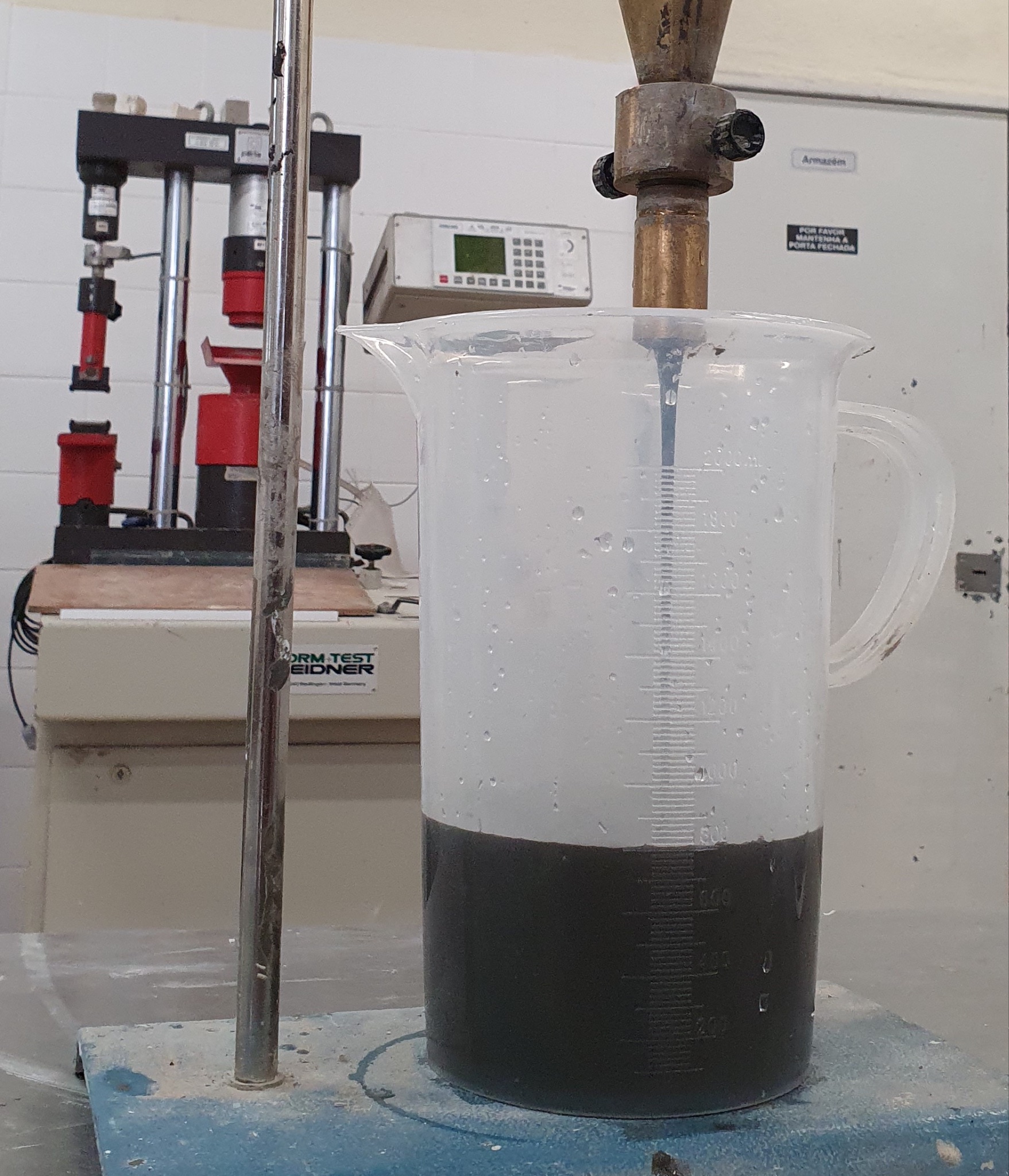

Performance of fresh concrete

The rheological properties and workability of the fresh concrete were analysed using established methods including:

Viskomat Flow;

Marsh Cone Test;

Table test.

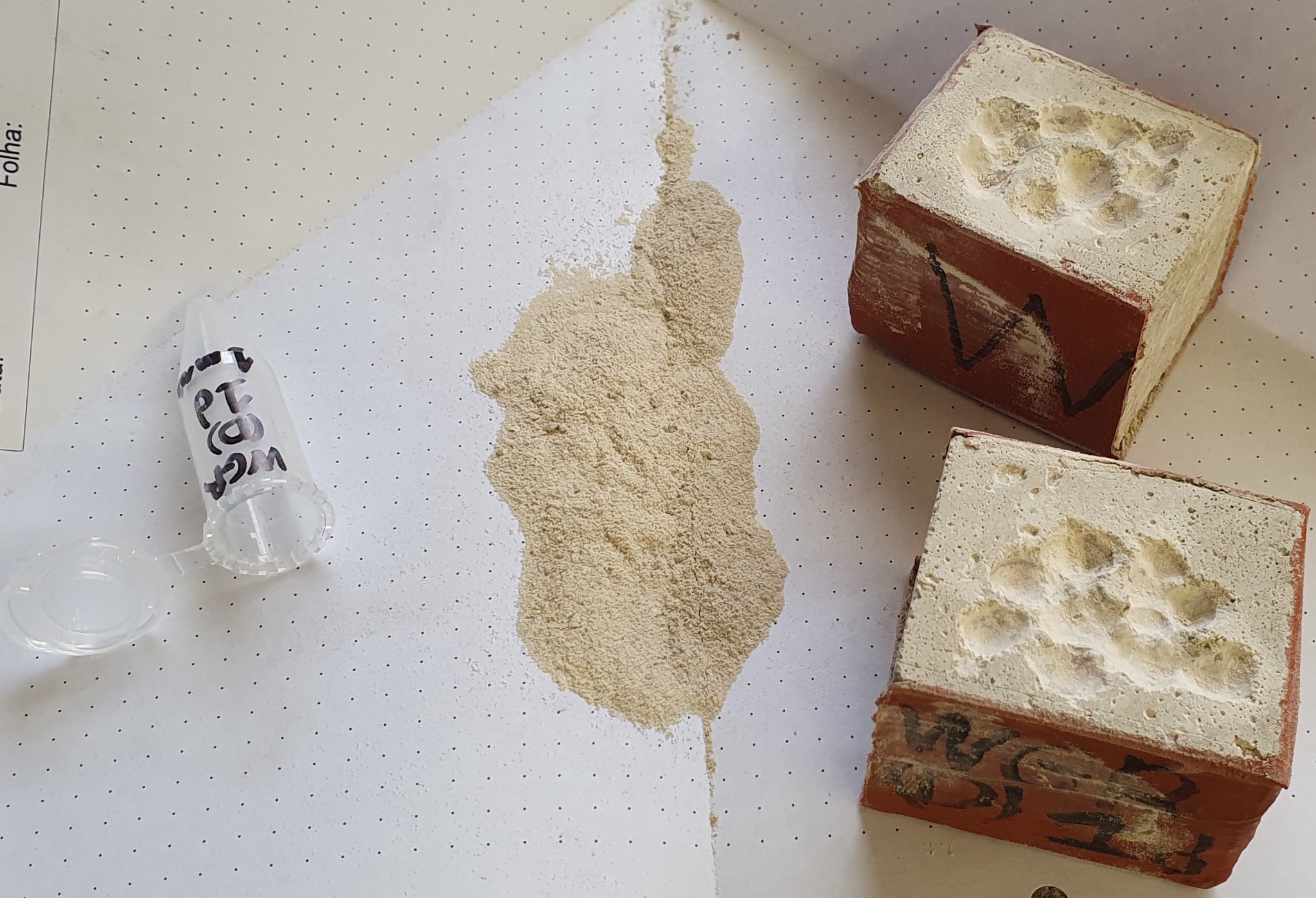

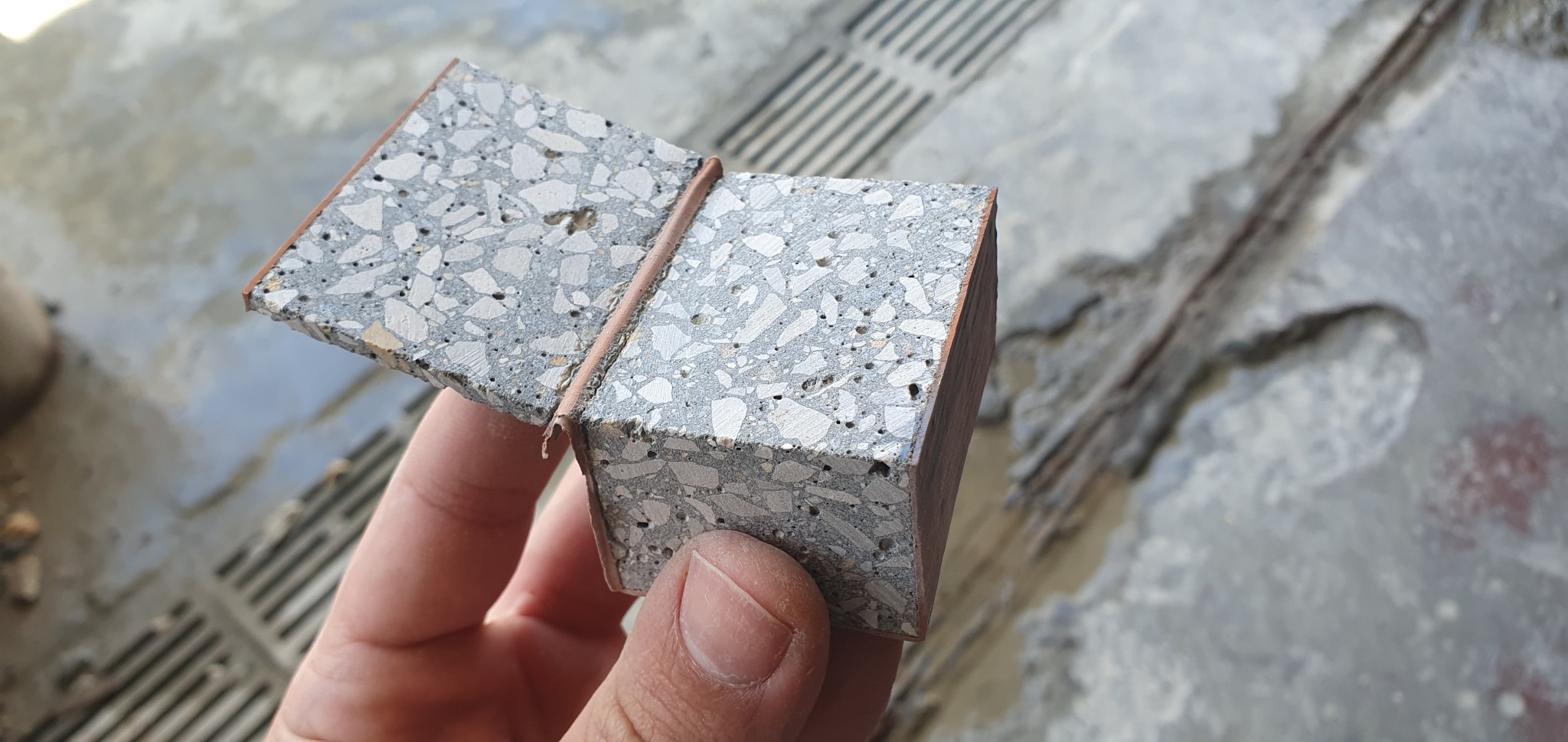

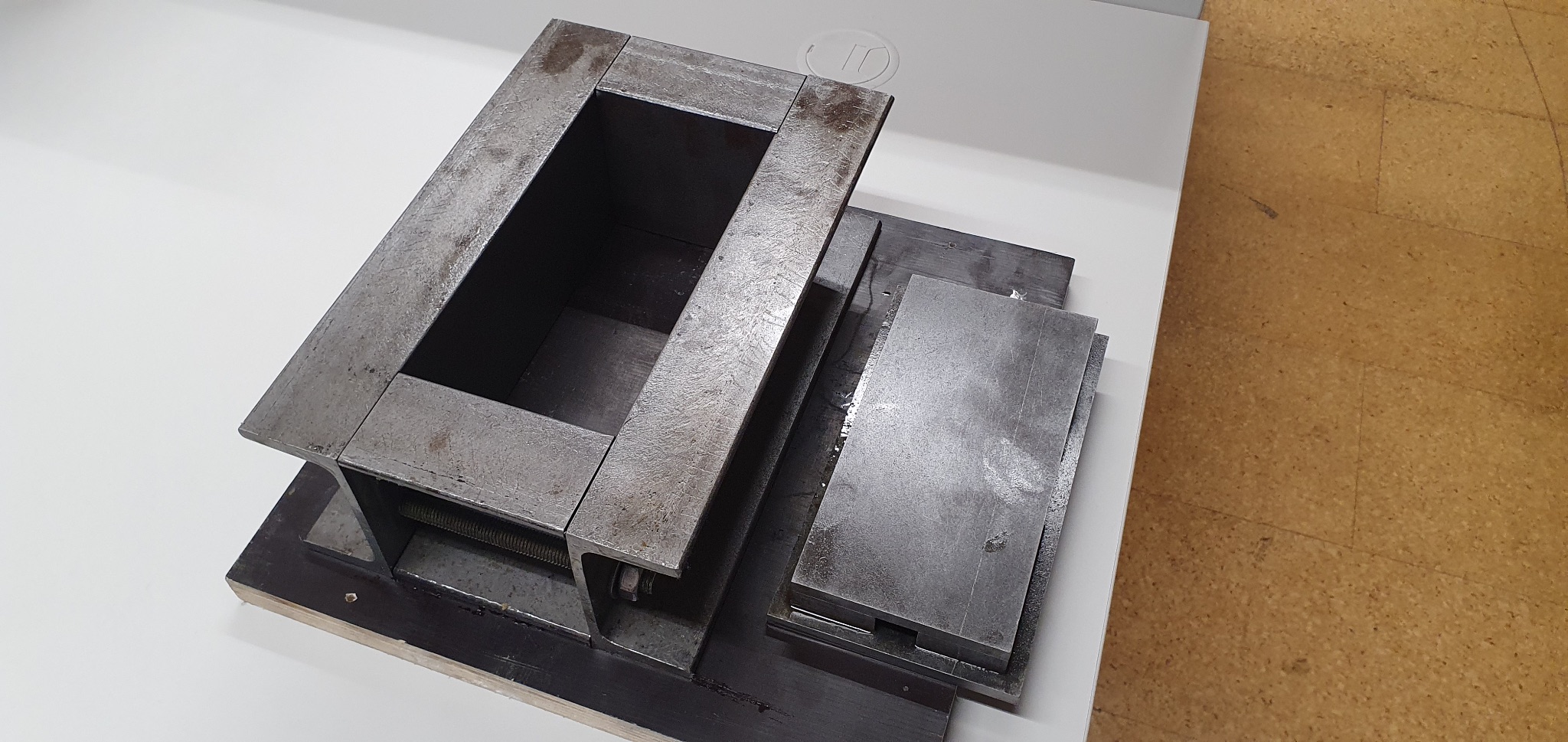

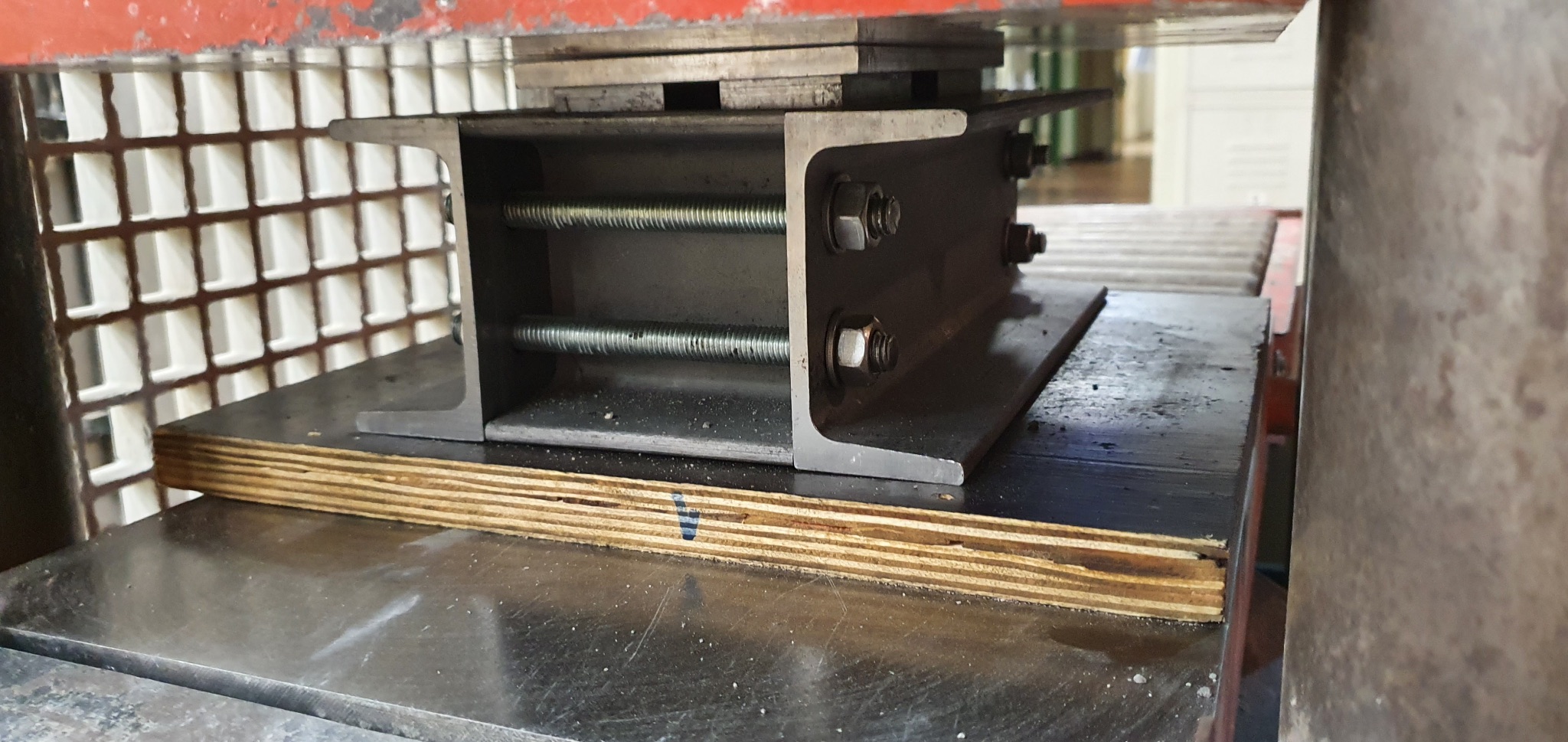

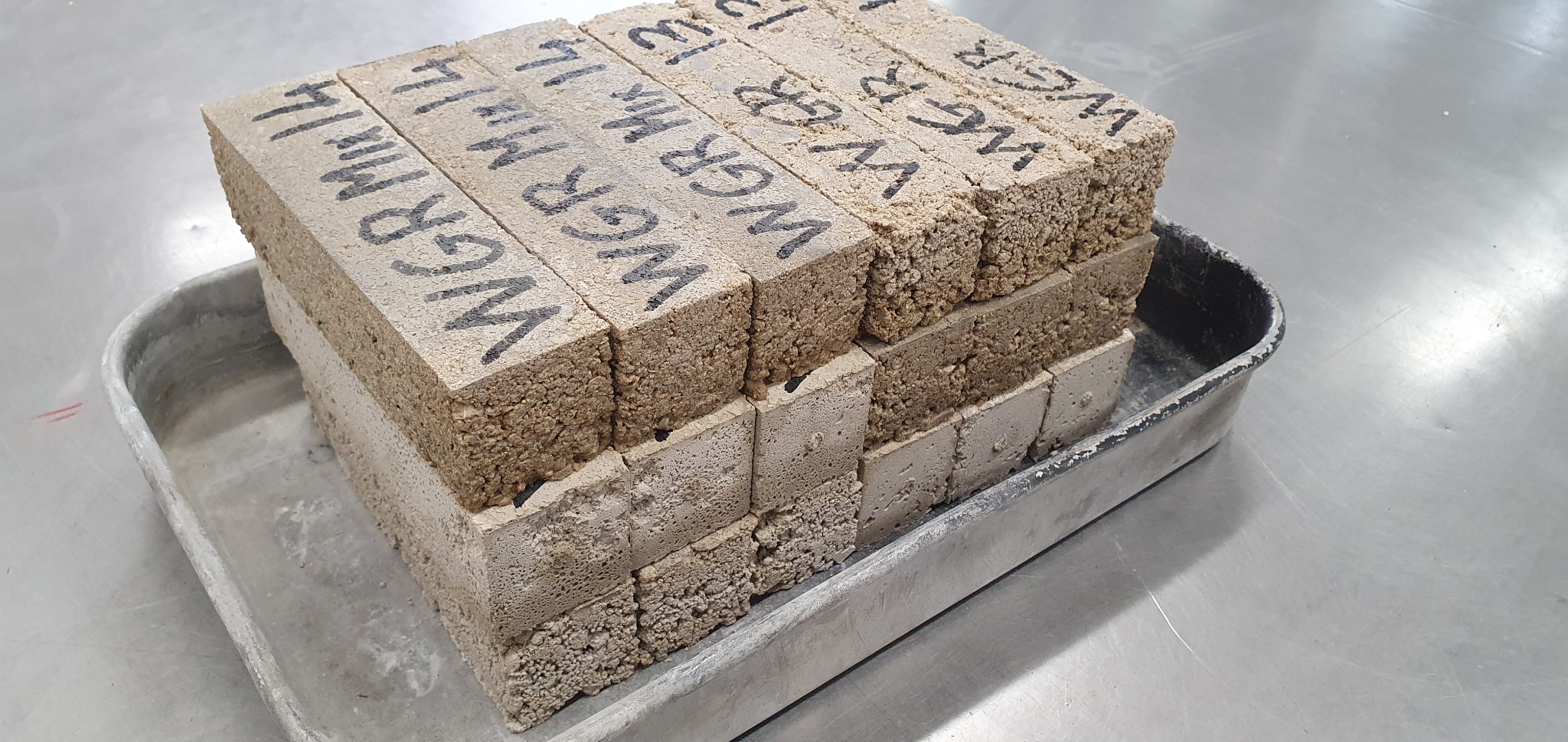

Production of non-structural precast concrete elements (CO2-enhanced concrete pavement blocks)

Using industrial waste materials as binders, conventional concrete pavement blocks were produced and tested by the standard:

Visual inspection;

Slip/skid resistance;

Splitting tensile strength;

Compressive strength;

Abrasion resistance;

Water absorption;

Thermal conductivity;

Freeze/thaw resistance.

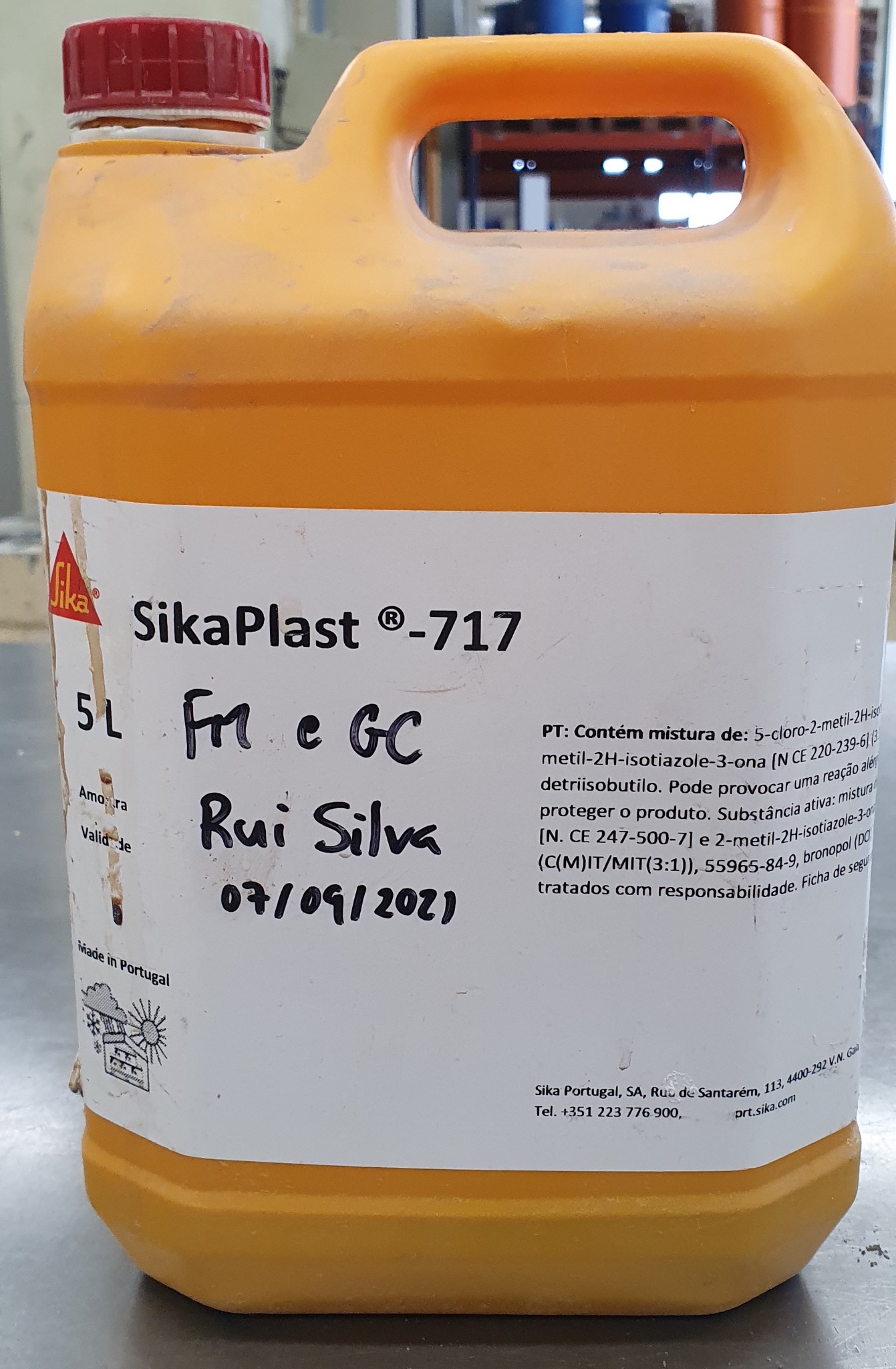

Enhancing the performance of alkali-activated concrete

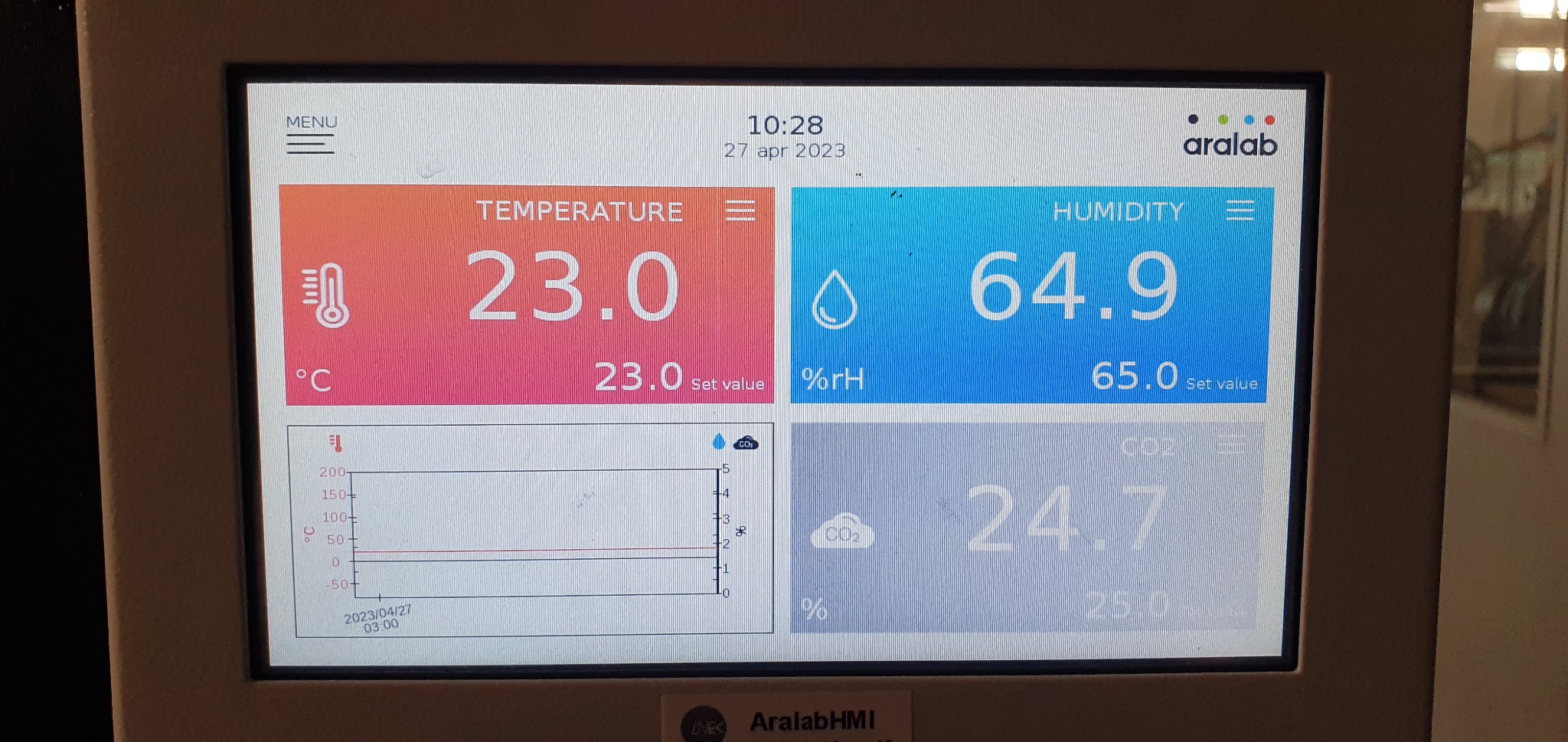

The performance of alkali-activated concrete made with industrial waste materials as binders is being enhanced through optimising aspects such as:

Density, workability, and water content;

Alkaline solution components concentrations;

Carbonation curing conditions (i.e. CO2 percentage, relative humidity, pressure, temperature, and curing duration).

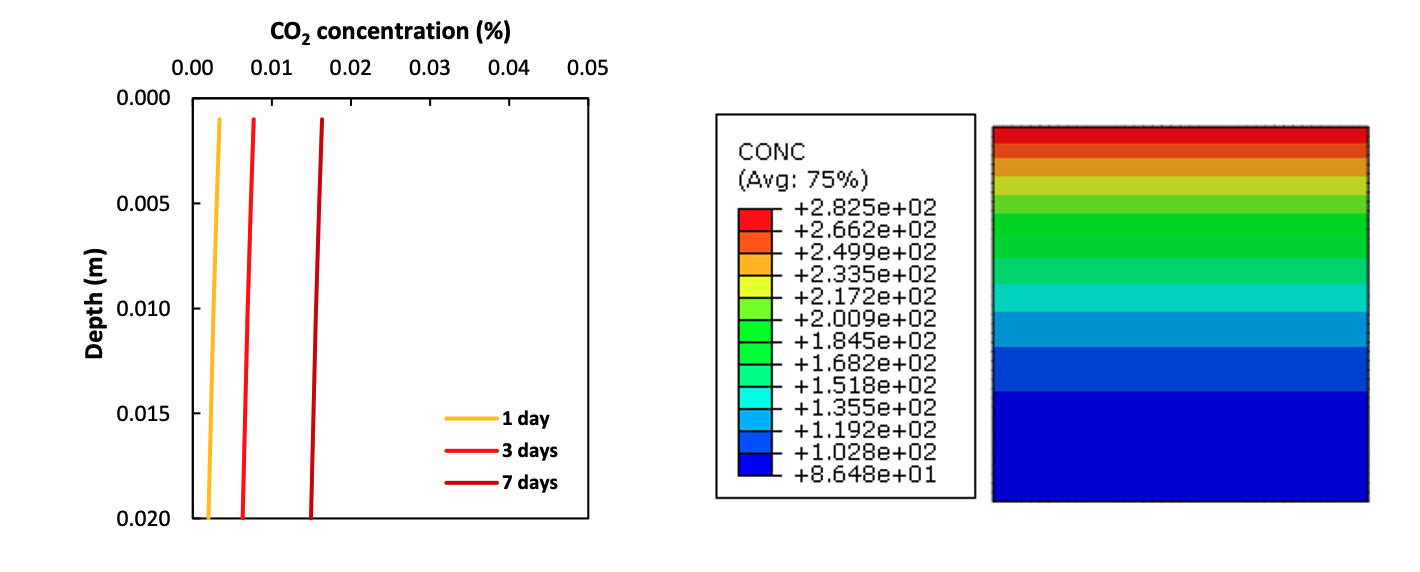

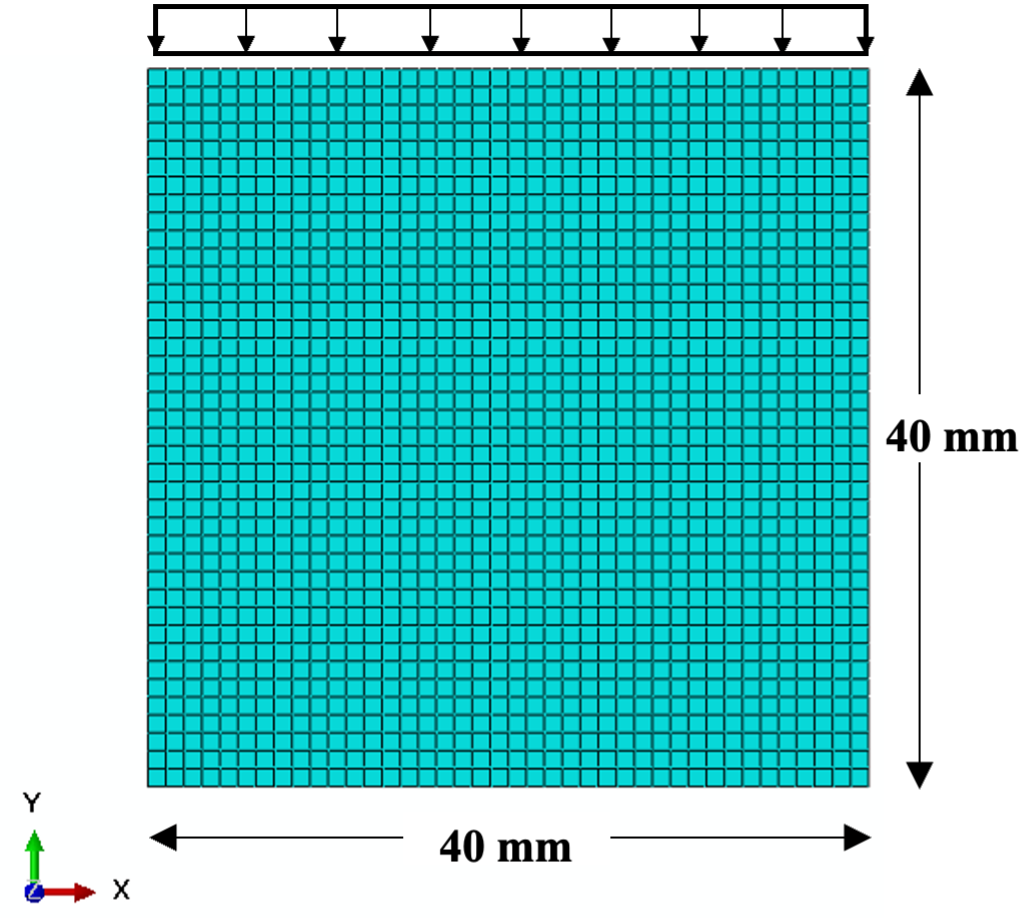

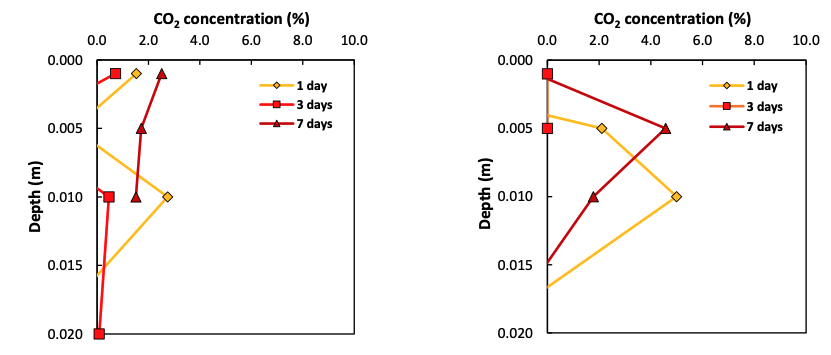

Numerical modelling of the CO2 diffusion

The CO2 diffusivity in mortar specimens with alkali-activated binders, including fly ash, municipal solid waste incinerator bottom ash, and waste glass rejects was investigated through the following steps:

Modelling of CO2 diffusivity in alkali-activated mortar specimens using ABAQUS;

Development of detailed finite element models and presented CO2 profiles for various diffusivity coefficients;

Identification of future research paths for validation, aiming to optimise material performance through parametric studies and develop coupled diffusivity-mechanical models for precast elements.